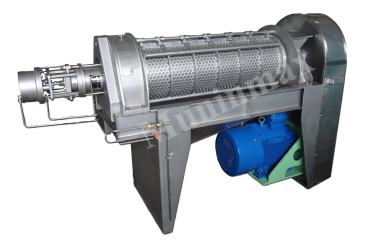

LOW PRESSURE EXTRACTOR

Cold Pressed Extractor

• Food industry : For Tropical fruit juice , Coconut/ Vegetable/ Herbal liquid and Oil

• Wastewater treatment industry

The advantage of the cold pressed is the extraction of the juice or liquid without heating and chemical additive. Principle process is separating liquid from the fruit, seed, leaf, peel, and flower with a low speed of screw pressed against back pressure to press liquid through the perforated screen set. Hence, the main benefit is keeping the natural taste, color and nutrition that has product value like Vitamin Enzyme and Bio-active

The screw press is composed of the following main equipments through

1.Inlet housing

2.Spindle screw set

3.Cone valve to back pressure

4.Perforated screen set

5.Outlet housing

6.Collected liquid basin

7.Complete set of Mechanical Driver

8.Complete set of Motorized Driver

9.Complete set of Pneumatic Driver

10.Skid & Base , Frame for above items

11.Electrical control panel unit

The principle of machine working procedure

Know well the fruit must be crushed before feeding into inlet housing (1) to get yield recovery and higher capacity. Then, spindle screw (2) carry on the fruit crushed to pass through and force along the screen set (4) that is attached and collaborate with both ends of inlet/ outlet housing (5). Regarding the perforated screen hole diameter, normally, it is about 0.5 to 1.5 mm- depending on the characteristics of the pulp. The liquid extract quantity depends on the pressure cone valve (3) against the edge of the outlet housing- meaning high pressure, high liquid yield, and high dryness of pomace.

Normally, the pressure is about 3.5-4.0 Barg for LP and VHP press which is forced by air cylinder and pneumatical system (9). Hence, the cone is moveable when the pressure in the screw press side is over than cone valve. Pomace will then be moved out pass-through outlet housing and transferred to the next process

Remark : Cone valve of HHP press is mechanism fix forced gap between screw press and cone valve rating is about 1.0-3.0 mm

Capacity and stage series process profitable

In the food industry, juice yield recovery and capacity utilization are highly important and hence, mostly their process is sequenced and arranged in priority followed by LP, HHP, and VHP (or belt press). Meat pomace from LP transfer to HHP and pomace from HHP transfer to VHP. This can be up to the capacity of about 5 MT/hour and the final pomace (waste) moisture (dryness) is about 68-70 % (moisture measurement, Roosting a sample at set point temperature to evaporate water without burning a sample. Roosting until not reducing in sample’s weight, Weight deficit at the beginning and the end is moisture content in the sample.) Know well capacity and yield recovery are related to the speed of spindle screw meat high capacity and opposite to yield recovery lower speed is higher yield because is more dryness

PHOTO