Why Drum Peelers Instead of Manual Peeling Method?

The traditional or manual way of peeling fruits has several drawbacks such as high labor intensity requirement, high risk of workplace accidents, high probability of waste pollution, and most importantly low efficiency due to manual labor and human errors. Using manual methods to peel the fruits cannot also meet the requirements of a mass production factory unless many labor costs have been invested. There is also the disadvantage of fruits’ discoloration and the possibility of going spoiled under the enzyme reaction during the process of manual peeling. For these reasons, it is the most effective way to invest in using a ‘Drum Peeler and Crusher‘ to peel the whole fruits in the process lines for mass production businesses. The principle behind these machines is that after the whole fruit is fed into the drum peeler, the rotary drums and knife set inside will instantly crush and separate the fruits from their peels and the meats. The meats produced can be used for further processing such as making fruit concentrates or juices.

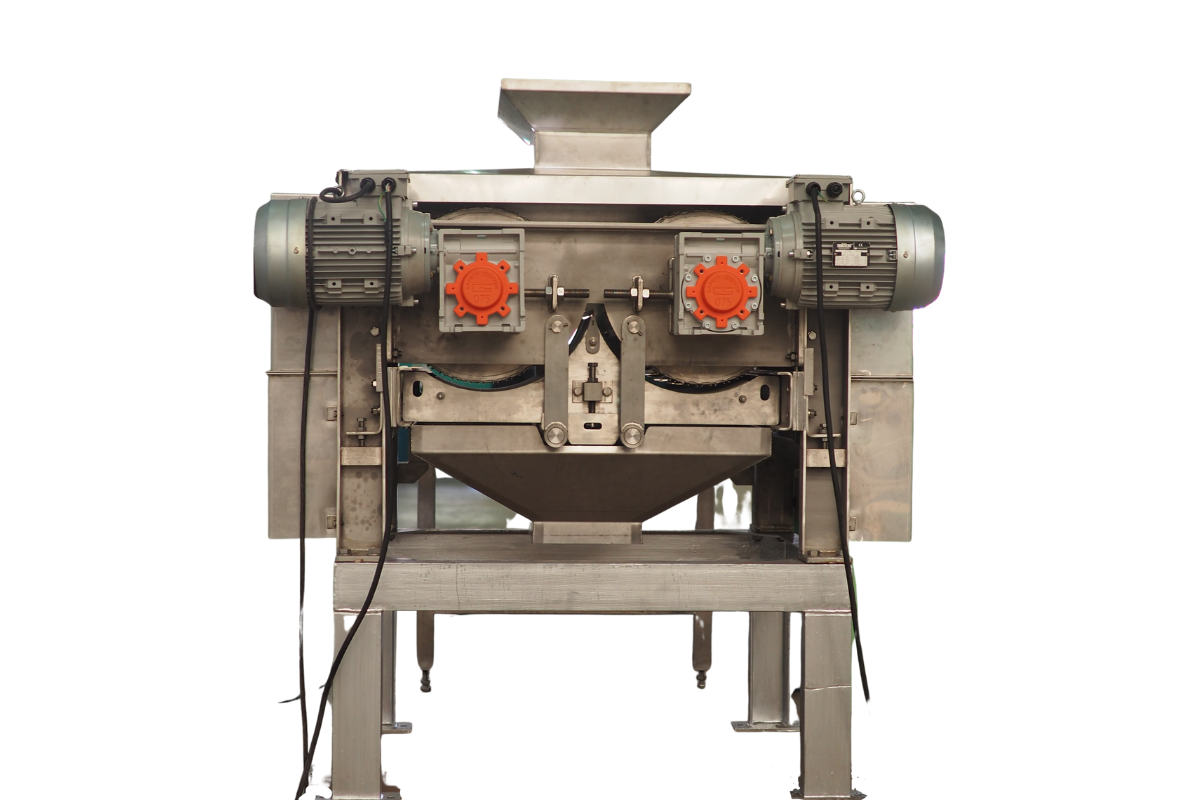

What is a MUNINMAX Drum Peeler and Crusher?

Drum Peeler and Crusher is a new product development created by MUNINMAX in 2020. It is designed to be able to handle whole fruits in different sizes according to the customers’ requirements. The machine has adjustable screws to adjust the drums inside suitable for a variety of sizes- from big-sized fruits like watermelon, cantaloupe, and papaya to smaller ones like pineapple and kiwi. There are two outlets on the sides to discharge the crushed peels and one outlet in the middle to collect the crushed meats. The feed capacity is 3t/h and the yield depends on the raw material used and the run time of the machine.

Watch this video below for better visualization of the whole process of MUNINMAX’s Drum Peelers and Crushers used for pineapples of different sizes.

If this kind of Drum peelers and crushers would be a good fit for your process lines, give us a call or contact us via info@muninmax.co.th for more details and quotations. Our team of professionals will get in touch with you within 24 hours with the perfect solutions for your pain points. As for the quality, MUNINMAX has been awarded ISO 9001:2015 standard, certificate numbers 14508, and 14509 by JAS-ANZ of Australia, and New Zealand. MUNINMAX also has over 25 years of industrial experience, making us your reliable partner for food and beverage process line installations! And no need to worry about flexibility and customization, as we always put the customers’ unique needs first when creating the designs and functions for each project!