A cooker machine, or pasteurizer, is a device used for heating and pasteurizing liquid foods such as beer, fruit juice, low-acid juice, and solid fruits. It operates at temperatures below 100°C to extend the shelf life of foods from several months to more than a year while preserving the sensory quality and nutritional value of the food with minimal changes.

How the Cooker Machine Works

Heating Process

- Hot Water Usage: Uses hot water at approximately 95-100°C to heat the food.

- Zoning: The hot water bath is divided into three zones: the first zone for initial heating, and the second and third zones for final heating and holding.

Temperature Control

- Temperature Difference: The temperature difference of the hot water must not exceed ±1.5°C to ensure effective microbial kill during the pasteurization process.

Cooling Process

- Post-Heating Cooling: After heating, the product is cooled in warm water and cold water baths.

- First Stage Cooling: Uses warm water at 50-60°C to reduce the risk of thermal shock for glass containers.

- Second Stage Cooling: Uses cooling water at 30-35°C to cool the product down to 38-42°C.

- Final Stage Cooling: Uses chilling water at 5-10°C to cool the product down to 10-15°C.

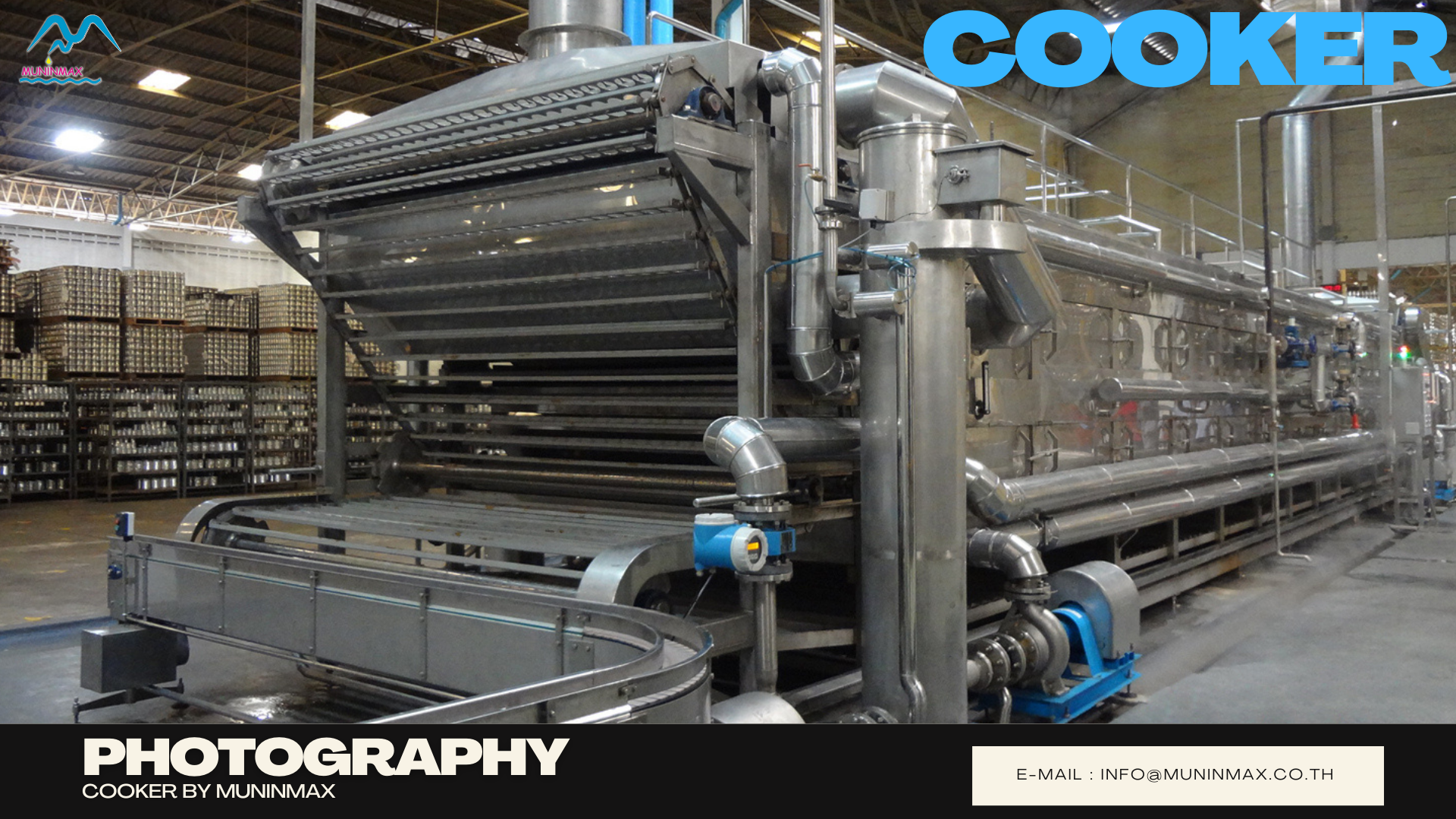

Special Features of the Cooker Machine

- Carrier Design: Custom-designed to fit the type, size, and shape of the container to prevent slipping or floating during transport through the cooking and cooling processes.

- Transport System: Uses a roller chain with bushings that rotate approximately 60 degrees every 400 mm to enhance the heat transfer coefficient through beneficial turbulence.

- Water Flow: Hot and cooling water flow counter to the direction of container transport, circulated by a high-flow, low-head pump to maximize the heat transfer coefficient, temperature distribution, and heat penetration.

Importance of the Cooker Machine

The cooker machine is essential for maintaining the quality and extending the shelf life of liquid foods by effectively controlling the heating and cooling processes.