A piston pump is equipment that operates by a seal pushed back and forth within a chamber, creating pressure and vacuum. Piston pumps are also used in high-exchange processes of food and beverage processing where pumping products without destroying the product’s integrity is as important as implementing heat exchange solutions to maintain product quality.

Piston Pumps are designed to handle delicate and viscous food products. This is to prevent from damaging the food particles while being pumped up at a very high pressure. Traditional pumping systems can cause problems for food processors that need to pump vegetables or fruits in pieces. Problems can arise not only from the high costs of traditional pumps but also from the low flow rates of lobular pumps, potential damages caused by cavity pumps, and low-pressure drops of double diaphragm pumps (1). Piston pumps can solve these problems and can be successfully applied in both food manufacturing industries and heavy-duty applications or other applications such as hydraulic systems, high-pressure water systems, and certain types of air compressors.

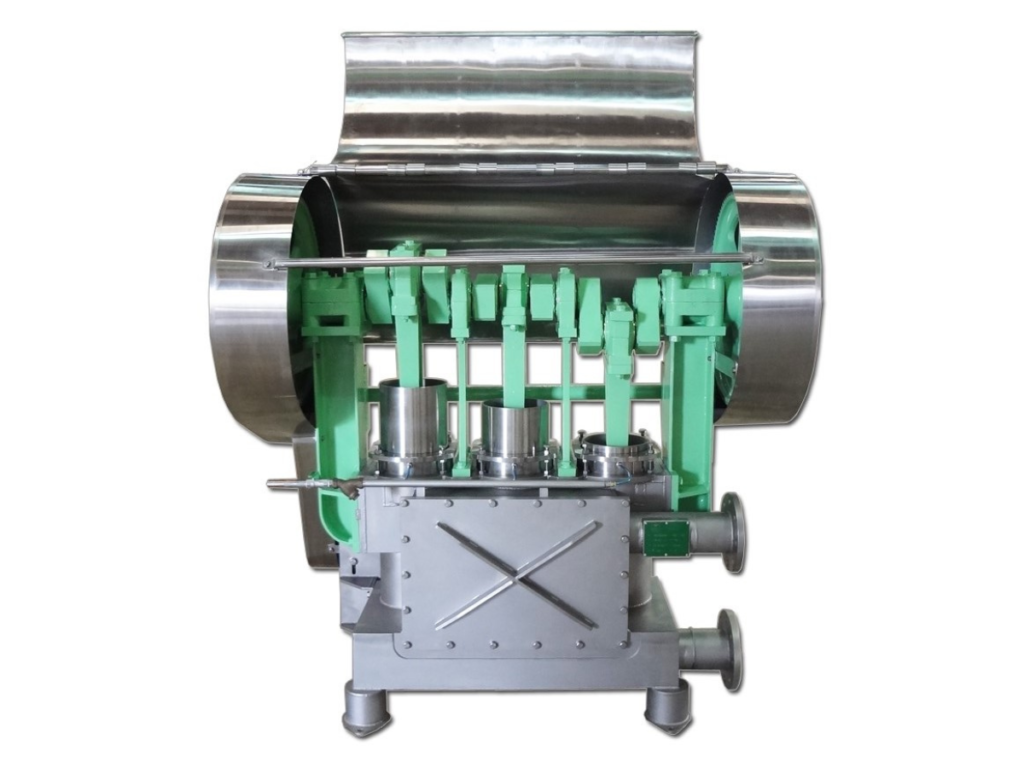

Piston pumps can be either a single piston or multiple pistons which are timed to operate at different intervals creating an even flow level (2). Here’s a general description of how a piston pump functions:

1. Piston and Cylinder: A cylindrical chamber and a piston that can move back and forth inside the cylinder mainly consists of a piston pump. The piston is designed to seal against the cylinder walls to prevent leaks happening.

2. Valves (Inlet and Outlet): Usually one-way valves or check valves are connected to the pump’s inlet and outlet to allow the fluid to enter and exit the pump while preventing reverse flow.

3. Action: The piston movements create a change in volume inside the cylinder. Once the piston moves away from the inlet, a vacuum is created inside the cylinder, causing the inlet valve to allow the fluid to be drawn into the chamber. When the piston goes toward the outlet, it reduces the volume causing the pressure to increase within the cylinder which in turn makes the outlet valve open and push the fluid out.

4. Repetition: The piston proceeds to move back and forth, creating suction for fluid to be drawn in and pressure to push the fluid via the outlet. Such repetition is the motion that allows the piston pump to move the fluid constantly.

MUNINMAX’s Piston Pumps

At MUNINMAX, we also offer quality Piston Pumps designed for Food and Beverage Processing lines. Contact MUNINMAX at [email protected] for more details or visit our website – www.muninmax.co.th to consult with our sales engineers and we will provide you with solutions that cater to your business needs like a glove!

References:

- https://www.hrs-heatexchangers.com/pumps-desc/pumps/

- https://www.northridgepumps.com/article-87_what-are-piston-pumps